Services

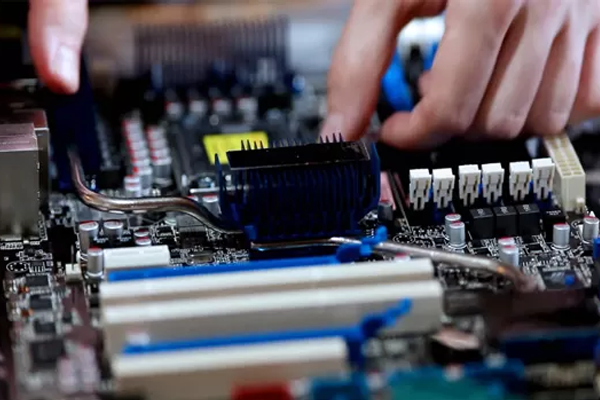

We offer a variety of services to complement our products and scope of business. From planning to after-sales, from design to after-commissioning, offering specialised third party inspection services our service portfolio features customer-friendly services to help you in any stage of industrial solutions on offer.

Committed to a distinctive, customer-service approach, Promed has earned a reputation of integrity and professionalism.

A full-service industrial automation integrator we support our customers through the entire integration process from the development of customized systems through Consultancy, Engineering Documentation, FAT, SAT, Onsite commissioning, Training and offering Annual Maintenance Contracts.

We provide conversion and upgrade services ( retrofitting ) to migrate from older platforms of existing Process/Industrial Automation equipment to newer platforms with advance automation features which can enhance efficiency and power saving.

- Electrical & Instrument Maintenance

- Mechanical Maintenance

- Extended Power Uprates (EPU)

- Instrumentation & calibration

- Plant Maintenance & Modifications

- Condition Monitory Services

- Third Party Inspection Services

- Outages, Shutdowns, & Turnarounds

- Plant ID Systems (bar coding, tagging)

- Electrical & Instrumentation Construction

- General & Specialty Construction Services

- Capital, Maintenance & Modification Projects

- Operation & Maintenance Training

- Thermographic Services

- Automation & System Integration

- Spares, New Components and Service

- Calibration & Certification

- Project reports

- Feasibility study

- HAZOP & HAZID

- Enginering and Design